Cotton is a soft, fluffy staple

fiber that grows in a

boll, or protective case, around the seeds of the cotton plants of the genus

Gossypium in the family of

Malvaceae. The fiber is almost pure

cellulose. Under natural conditions, the cotton bolls will tend to increase the dispersal of the seeds.

[clarification needed]

The plant is a

shrub

native to tropical and subtropical regions around the world, including

the Americas, Africa, and India. The greatest diversity of wild cotton

species is found in Mexico, followed by Australia and Africa.

[1] Cotton was independently domesticated in the Old and New Worlds.

The fiber is most often spun into

yarn or thread and used to make a soft,

breathable textile.

The use of cotton for fabric is known to date to prehistoric times;

fragments of cotton fabric dated from 5000 BC have been excavated in

Mexico and between 6000 BC and 5000 BC in the

Indus Valley Civilization. Although cultivated since antiquity, it was the invention of the

cotton gin that lowered the cost of production that led to its widespread use, and it is the most widely used

natural fiber cloth in clothing today.

Current estimates for world production are about 25 million

tonnes

or 110 million bales annually, accounting for 2.5% of the world's

arable land. China is the world's largest producer of cotton, but most

of this is used domestically. The United States has been the largest

exporter for many years.

[2]

In the United States, cotton is usually measured in bales, which

measure approximately 0.48 cubic meters (17 cubic feet) and weigh 226.8

kilograms (500 pounds).

[3]

Types

There are four commercially grown species of cotton, all domesticated in antiquity:

The two New World cotton species account for the vast majority of

modern cotton production, but the two Old World species were widely used

before the 1900s. While cotton fibers occur naturally in colors of

white, brown, pink and green, fears of contaminating the genetics of

white cotton have led many cotton-growing locations to ban the growing

of colored cotton varieties.

History

Indian subcontinent

Indus Valley Civilization, Early Phase (3300-2600 BC)

The earliest evidence of cotton use in the

Indian subcontinent has been found at the site of

Mehrgarh and

Rakhigarhi where cotton threads have been found preserved in copper beads; these finds have been dated to

Neolithic (between 6000 and 5000 BC).

[4][5] Cotton cultivation in the region is dated to the

Indus Valley Civilization, which covered parts of modern eastern Pakistan and northwestern India between 3300 and 1300 BC.

[6]

The Indus cotton industry was well-developed and some methods used in

cotton spinning and fabrication continued to be used until the

industrialization of India.

[7] Between 2000 and 1000 BC cotton became widespread across much of India.

[8] For example, it has been found at the site of

Hallus in

Karnataka dating from around 1000 BC.

[9]

Mexico

Peru

In

Peru, cultivation of the indigenous cotton species

Gossypium barbadense has been dated, from a find in Ancon, to c 4200 BC,

[12] and was the backbone of the development of coastal cultures such as the

Norte Chico,

Moche, and

Nazca.

Cotton was grown upriver, made into nets, and traded with fishing

villages along the coast for large supplies of fish. The Spanish who

came to Mexico and Peru in the early 16th century found the people

growing cotton and wearing clothing made of it.

Arabia

Cotton has been spun, woven, and dyed since prehistoric times. It

clothed the people of ancient India, Egypt, and China. Hundreds of years

before the Christian era, cotton textiles were woven in India with

matchless skill, and their use spread to the Mediterranean countries.

Iran

In Iran (

Persia), the history of cotton dates back to the

Achaemenid

era (5th century BC); however, there are few sources about the planting

of cotton in pre-Islamic Iran. The planting of cotton was common in

Merv,

Ray and

Pars of Iran. In

Persian poets' poems, especially

Ferdowsi's

Shahname, there are references to cotton ("panbe" in

Persian).

Marco Polo (13th century) refers to the major products of Persia, including cotton.

John Chardin, a French traveler of the 17th century who visited the

Safavid Persia, spoke approvingly of the vast cotton farms of Persia.

[13]

China

During the

Han dynasty (207 BC - 220 AD), cotton was grown by Chinese peoples in the southern Chinese province of

Yunnan.

[14]

Egypt

Though known since antiquity the commercial growing of cotton in

Egypt only started in 1820's, following a Frenchman, by the name of M.

Jumel, propositioning the then ruler,

Mohamed Ali Pasha,

that he could earn a substantial income by growing an extra-long staple

Maho (Barbadence) cotton, in Lower Egypt, for the French market.

Mohamed Ali Pasha accepted the proposition and granted himself the

monopoly on the sale and export of cotton in Egypt; and later dictated

cotton should be grown in preference to other crops. By the time of the

American Civil war annual exports had reached $16 million (120,000

bales), which rose to $56 million by 1864, primarily due to the loss of

the Confederate supply on the world market. Exports continued to grow

even after the reintroduction of US cotton, produced now by a paid

workforce, and Egyptian exports reached 1.2 million bales a year by

1903.

Europe

During the late medieval period, cotton became known as an imported

fiber in northern Europe, without any knowledge of how it was derived,

other than that it was a plant. Because

Herodotus had written in his

Histories,

Book III, 106, that in India trees grew in the wild producing wool, it

was assumed that the plant was a tree, rather than a shrub. This aspect

is retained in the name for cotton in several Germanic languages, such

as German

Baumwolle, which translates as "tree wool" (

Baum means "tree";

Wolle

means "wool"). Noting its similarities to wool, people in the region

could only imagine that cotton must be produced by plant-borne sheep.

John Mandeville,

writing in 1350, stated as fact the now-preposterous belief: "There

grew there [India] a wonderful tree which bore tiny lambs on the endes

of its branches. These branches were so pliable that they bent down to

allow the lambs to feed when they are hungrie [

sic]." (See

Vegetable Lamb of Tartary.) By the end of the 16th century, cotton was cultivated throughout the warmer regions in Asia and the Americas.

India's cotton-processing sector gradually declined during British expansion in India and the establishment of

colonial rule during the late 18th and early 19th centuries. This was largely due to aggressive colonialist mercantile policies of the

British East India Company,

which made cotton processing and manufacturing workshops in India

uncompetitive. Indian markets were increasingly forced to supply only

raw cotton and, by British-imposed law, to purchase manufactured

textiles from Britain.

[citation needed]

Industrial Revolution in Britain

The advent of the

Industrial Revolution in Britain provided a great boost to cotton manufacture, as textiles emerged as Britain's leading export. In 1738,

Lewis Paul and

John Wyatt, of

Birmingham,

England, patented the roller spinning machine, as well as the

flyer-and-bobbin system for drawing cotton to a more even thickness

using two sets of rollers that traveled at different speeds. Later, the

invention of the

James Hargreaves'

spinning jenny in 1764,

Richard Arkwright's

spinning frame in 1769 and

Samuel Crompton's

spinning mule

in 1775 enabled British spinners to produce cotton yarn at much higher

rates. From the late 18th century on, the British city of

Manchester acquired the nickname

"Cottonopolis" due to the cotton industry's omnipresence within the city, and Manchester's role as the heart of the global cotton trade.

Production capacity in Britain and the United States was improved by the invention of the

cotton gin by the American

Eli Whitney

in 1793. Before the development of cotton gins, the cotton fibers had

to be pulled from the seeds tediously by hand. By the late 1700s a

number of crude ginning machines had been developed. However, to produce

a bale of cotton required over 600 hours of human labor,

[15]

making large-scale production uneconomical in the United States, even

with the use of humans as slave labor. The gin that Whitney manufactured

(the Holmes design) reduced the hours down to just a dozen or so per

bale. Although Whitney patented his own design for a cotton gin, he

manufactured a prior design from

Henry Odgen Holmes, for which Holmes filed a patent in 1796.

[15]

Improving technology and increasing control of world markets allowed

British traders to develop a commercial chain in which raw cotton fibers

were (at first) purchased from

colonial plantations, processed into cotton cloth in the mills of

Lancashire, and then exported on British ships to captive colonial markets in

West Africa,

India, and China (via Shanghai and Hong Kong).

By the 1840s, India was no longer capable of supplying the vast

quantities of cotton fibers needed by mechanized British factories,

while shipping bulky, low-price cotton from India to Britain was

time-consuming and expensive. This, coupled with the emergence of

American cotton as a superior type (due to the longer, stronger fibers

of the two domesticated native American species,

Gossypium hirsutum and

Gossypium barbadense), encouraged British traders to purchase cotton from

plantations in the United States and

plantations in the

Caribbean. By the mid-19th century, "

King Cotton" had become the backbone of the

southern American economy. In the United States, cultivating and harvesting cotton became the leading occupation of

slaves.

During this time, cotton cultivation in the

British Empire,

especially Australia and India, greatly increased to replace the lost

production of the American South. Through tariffs and other

restrictions, the British government discouraged the production of

cotton cloth in India; rather, the raw fiber was sent to England for

processing. The Indian

Mahatma Gandhi described the process:

- English people buy Indian cotton in the field, picked by Indian labor at seven cents a day, through an optional monopoly.

- This cotton is shipped on British ships, a three-week journey across

the Indian Ocean, down the Red Sea, across the Mediterranean, through

Gibraltar, across the Bay of Biscay and the Atlantic Ocean to London.

One hundred per cent profit on this freight is regarded as small.

- The cotton is turned into cloth in Lancashire. You pay shilling

wages instead of Indian pennies to your workers. The English worker not

only has the advantage of better wages, but the steel companies of

England get the profit of building the factories and machines. Wages;

profits; all these are spent in England.

- The finished product is sent back to India at European shipping

rates, once again on British ships. The captains, officers, sailors of

these ships, whose wages must be paid, are English. The only Indians who

profit are a few lascars who do the dirty work on the boats for a few

cents a day.

- The cloth is finally sold back to the kings and landlords of India

who got the money to buy this expensive cloth out of the poor peasants

of India who worked at seven cents a day.[16]

US

In the United States, Southern cotton provided capital for the

continuing development of the North. The cotton produced by enslaved

African Americans not only helped the South, but also enriched Northern

merchants. Much of the Southern cotton was trans-shipped through

northern

ports.

Cotton remained a key crop in the Southern economy after

emancipation and the end of the Civil War in 1865. Across the South,

sharecropping

evolved, in which landless black and white farmers worked land owned by

others in return for a share of the profits. Some farmers rented the

land and bore the production costs themselves. Until mechanical cotton

pickers were developed, cotton farmers needed additional labor to

hand-pick cotton. Picking cotton was a source of income for families

across the South. Rural and small town school systems had split

vacations so children could work in the fields during "cotton-picking."

It was not until the 1950s that reliable harvesting machinery was

introduced (prior to this, cotton-harvesting machinery had been too

clumsy to pick cotton without shredding the fibers). During the first

half of the 20th century, employment in the cotton industry fell, as

machines began to replace laborers and the South's rural labor force

dwindled during the

World Wars.

Cotton remains a major export of the

southern United States, and a majority of the world's annual cotton crop is of the long-staple American variety.

[17]

Cultivation

A cotton field, late in the season

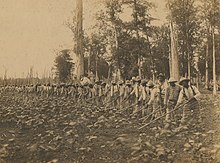

Picking cotton in

Armenia in the 1930s. No cotton is grown there today.

Cotton modules in Australia (2007)

Successful cultivation of cotton requires a long

frost-free period, plenty of sunshine, and a moderate rainfall, usually from 60 to 120 cm (24 to 47 in).

Soils usually need to be fairly heavy, although the level of

nutrients

does not need to be exceptional. In general, these conditions are met

within the seasonally dry tropics and subtropics in the Northern and

Southern hemispheres, but a large proportion of the cotton grown today

is cultivated in areas with less rainfall that obtain the water from

irrigation. Production of the crop for a given year usually starts soon

after harvesting the preceding autumn. Cotton is naturally a perennial

but is grown as an annual to help control pests.

[18]

Planting time in spring in the Northern hemisphere varies from the

beginning of February to the beginning of June. The area of the United

States known as the

South Plains

is the largest contiguous cotton-growing region in the world. While

dryland (non-irrigated) cotton is successfully grown in this region,

consistent yields are only produced with heavy reliance on

irrigation water drawn from the

Ogallala Aquifer. Since cotton is somewhat salt and drought tolerant, this makes it an attractive crop for arid and semiarid regions. As

water resources

get tighter around the world, economies that rely on it face

difficulties and conflict, as well as potential environmental problems.

[19][20][21][22][23] For example, improper cropping and irrigation practices have led to

desertification in areas of

Uzbekistan, where cotton is a major export. In the days of the

Soviet Union, the

Aral Sea was tapped for agricultural irrigation, largely of cotton, and now

salination is widespread.

[22][23]

Cotton can also be cultivated to have colors other than the yellowish off-white typical of modern commercial cotton fibers.

Naturally colored cotton can come in red, green, and several shades of brown.

[24]

Genetic modification

Genetically modified (GM) cotton was developed to reduce the heavy reliance on pesticides. The bacterium

Bacillus thuringiensis (Bt) naturally produces a chemical harmful only to a small fraction of insects, most notably the larvae of

moths and butterflies,

beetles, and

flies, and harmless to other forms of life.

[25][26][27] The gene coding for Bt toxin has been inserted into cotton, causing cotton, called

Bt cotton, to produce this natural insecticide in its tissues. In many regions, the main pests in commercial cotton are

lepidopteran

larvae, which are killed by the Bt protein in the transgenic cotton

they eat. This eliminates the need to use large amounts of

broad-spectrum insecticides to kill lepidopteran pests (some of which

have developed

pyrethroid

resistance). This spares natural insect predators in the farm ecology

and further contributes to noninsecticide pest management.

But Bt cotton is ineffective against many cotton pests, however, such as

plant bugs,

stink bugs, and

aphids;

depending on circumstances it may still be desirable to use

insecticides against these. A 2006 study done by Cornell researchers,

the Center for Chinese Agricultural Policy and the Chinese Academy of

Science on Bt cotton farming in China found that after seven years these

secondary pests that were normally controlled by pesticide had

increased, necessitating the use of pesticides at similar levels to

non-Bt cotton and causing less profit for farmers because of the extra

expense of GM seeds.

[28] However, a 2009 study by the Chinese Academy of Sciences, Stanford University and Rutgers University refuted this.

[29]

They concluded that the GM cotton effectively controlled bollworm. The

secondary pests were mostly miridae (plant bugs) whose increase was

related to local temperature and rainfall and only continued to increase

in half the villages studied. Moreover, the increase in insecticide use

for the control of these secondary insects was far smaller than the

reduction in total insecticide use due to Bt cotton adoption. A 2012

Chinese study concluded that Bt cotton halved the use of pesticides and

doubled the level of ladybirds, lacewings and spiders.

[30][31] The

International Service for the Acquisition of Agri-biotech Applications (ISAAA) said that, worldwide, GM cotton was planted on an area of 25 million hectares in 2011.

[32] This was 69% of the worldwide total area planted in cotton.

GM cotton acreage in India grew at a rapid rate, increasing from

50,000 hectares in 2002 to 10.6 million hectares in 2011. The total

cotton area in India was 12.1 million hectares in 2011, so GM cotton was

grown on 88% of the cotton area. This made India the country with the

largest area of GM cotton in the world.

[32] A long-term study on the economic impacts of Bt cotton in India, published in the Journal

PNAS in 2012, showed that Bt cotton has increased yields, profits, and living standards of smallholder farmers.

[33]

The U.S. GM cotton crop was 4.0 million hectares in 2011 the second

largest area in the world, the Chinese GM cotton crop was third largest

by area with 3.9 million hectares and Pakistan had the fourth largest GM

cotton crop area of 2.6 million hectares in 2011.

[32]

The initial introduction of GM cotton proved to be a success in

Australia – the yields were equivalent to the non-transgenic varieties

and the crop used much less pesticide to produce (85% reduction).

[34]

The subsequent introduction of a second variety of GM cotton led to

increases in GM cotton production until 95% of the Australian cotton

crop was GM in 2009

[35] making Australia the country with the fifth largest GM cotton crop in the world.

[32]

Other GM cotton growing countries in 2011 were Argentina, Myanmar,

Burkina Faso, Brazil, Mexico, Colombia, South Africa and Costa Rica.

[32]

Cotton has been genetically modified for resistance to

glyphosate

a broad-spectrum herbicide discovered by Monsanto which also sells some

of the Bt cotton seeds to farmers. There are also a number of other

cotton seed companies selling GM cotton around the world. About 62% of

the GM cotton grown from 1996 to 2011 was insect resistant, 24%

stacked product and 14% herbicide resistant.

[32]

Cotton has

gossypol,

a toxin that makes it inedible. However, scientists have silenced the

gene that produces the toxin, making it a potential food crop.

[36]

Organic production

Organic cotton is generally understood as cotton from plants not

genetically modified and that is certified to be grown without the use of any synthetic agricultural chemicals, such as

fertilizers or

pesticides.

[37] Its production also promotes and enhances biodiversity and biological cycles.

[38] In the United States, organic cotton plantations are required to enforce the

National Organic Program (NOP). This institution determines the allowed practices for pest control, growing, fertilizing, and handling of organic crops.

[39][40]

As of 2007, 265,517 bales of organic cotton were produced in 24

countries, and worldwide production was growing at a rate of more than

50% per year.

[41]

Pests and weeds

The cotton industry relies heavily on chemicals, such as

herbicides,

fertilizers and

insecticides, although a very small number of farmers are moving toward an

organic

model of production, and organic cotton products are now available for

purchase at limited locations. These are popular for baby clothes and

diapers. Under most definitions, organic products do not use

genetic engineering. All natural cotton products are known to be both sustainable and hypoallergenic.

Historically, in North America, one of the most economically destructive pests in cotton production has been the

boll weevil. Due to the

US Department of Agriculture's highly successful

Boll Weevil Eradication Program

(BWEP), this pest has been eliminated from cotton in most of the United

States. This program, along with the introduction of genetically

engineered

Bt cotton (which contains a

bacterial gene that codes for a plant-produced

protein that is toxic to a number of pests such as

cotton bollworm and

pink bollworm), has allowed a reduction in the use of synthetic insecticides.

Harvesting

Offloading freshly harvested cotton into a module builder in

Texas; previously built modules can be seen in the background

Cotton being picked by hand in

India, 2005.

Most cotton in the United States, Europe and Australia is harvested

mechanically, either by a cotton picker, a machine that removes the

cotton from the boll without damaging the cotton plant, or by a cotton

stripper, which strips the entire boll off the plant. Cotton strippers

are used in regions where it is too windy to grow picker varieties of

cotton, and usually after application of a chemical

defoliant

or the natural defoliation that occurs after a freeze. Cotton is a

perennial crop in the tropics, and without defoliation or freezing, the

plant will continue to grow.

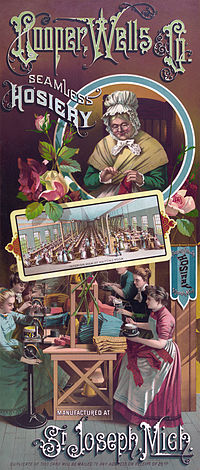

Competition from synthetic fibers

The era of manufactured fibers began with the development of

rayon

in France in the 1890s. Rayon is derived from a natural cellulose and

cannot be considered synthetic, but requires extensive processing in a

manufacturing process, and led the less expensive replacement of more

naturally derived materials. A succession of new synthetic fibers were

introduced by the chemicals industry in the following decades.

Acetate in fiber form was developed in 1924.

Nylon,

the first fiber synthesized entirely from petrochemicals, was

introduced as a sewing thread by DuPont in 1936, followed by DuPont's

acrylic in 1944. Some garments were created from fabrics based on these fibers, such as women's

hosiery from nylon, but it was not until the introduction of

polyester into the fiber marketplace in the early 1950s that the market for cotton came under threat.

[43]

The rapid uptake of polyester garments in the 1960s caused economic

hardship in cotton-exporting economies, especially in Central American

countries, such as

Nicaragua,

where cotton production had boomed tenfold between 1950 and 1965 with

the advent of cheap chemical pesticides. Cotton production recovered in

the 1970s, but crashed to pre-1960 levels in the early 1990s.

[44]

Uses

Cotton is used to make a number of textile products. These include

terrycloth for highly absorbent bath

towels and

robes;

denim for

blue jeans;

cambric, popularly used in the manufacture of blue work shirts (from which we get the term "

blue-collar"); and

corduroy,

seersucker, and cotton

twill.

Socks,

underwear, and most

T-shirts are made from cotton. Bed sheets often are made from cotton. Cotton also is used to make yarn used in

crochet and

knitting.

Fabric also can be made from recycled or recovered cotton that

otherwise would be thrown away during the spinning, weaving, or cutting

process. While many fabrics are made completely of cotton, some

materials blend cotton with other fibers, including

rayon and

synthetic fibers such as

polyester.

It can either be used in knitted or woven fabrics, as it can be blended

with elastine to make a stretchier thread for knitted fabrics, and

apparel such as stretch jeans. Cotton can be blended also with

linen

as Linen-cotton blends which give benefit of both plant materials which

wrinkle resistant, lightweight, breathable and can keep heat more

effectively than only linen. These blends are thinner and lighter, but

stronger than only cotton.

[45]

The cottonseed which remains after the cotton is ginned is used to produce

cottonseed oil, which, after refining, can be consumed by humans like any other

vegetable oil. The

cottonseed meal that is left generally is fed to

ruminant livestock; the

gossypol remaining in the meal is toxic to

monogastric

animals. Cottonseed hulls can be added to dairy cattle rations for

roughage. During the American slavery period, cotton root bark was used

in

folk remedies as an

abortifacient,

that is, to induce a miscarriage. Gossypol was one of the many

substances found in all parts of the cotton plant and it was described

by the scientists as 'poisonous pigment'. It also appears to inhibit the

development of sperm or even restrict the mobility of the sperm. Also,

it is thought to interfere with the menstrual cycle by restricting the

release of certain hormones.

[46]

Cotton linters are fine, silky fibers which adhere to the seeds of

the cotton plant after ginning. These curly fibers typically are less

than

1⁄8 inch

(3.2 mm) long. The term also may apply to the longer textile fiber

staple lint as well as the shorter fuzzy fibers from some upland

species. Linters are traditionally used in the manufacture of paper and

as a raw material in the manufacture of

cellulose. In the UK, linters are referred to as "cotton wool". This can also be a refined product (

absorbent cotton in U.S. usage) which has

medical,

cosmetic and many other practical uses. The first medical use of cotton wool was by

Sampson Gamgee at the Queen's Hospital (later the General Hospital) in

Birmingham, England.

Shiny cotton is a processed version of the fiber that can be made into cloth resembling

satin

for shirts and suits. However, it is hydrophobic (does not absorb water

easily), which makes it unfit for use in bath and dish towels (although

examples of these made from shiny cotton are seen).

The name

Egyptian cotton

is broadly associated with quality products, however only a small

percentage of "Egyptian cotton" products are actually of superior

quality. Most products bearing the name are not made with cotton from

Egypt.

[47]

Pima cotton is often compared to Egyptian cotton, as both are used in

high quality bed sheets and other cotton products. It is considered the

next best quality after high quality Egyptian cotton by some

authorities. Pima cotton is grown in the American southwest. Not all

products bearing the Pima name are made with the finest cotton. The Pima

name is now used by cotton-producing nations such as Peru, Australia

and Israel.

[48]

Cotton lisle is a finely-spun, tightly twisted type of cotton that is

noted for being strong and durable. Lisle is composed of two strands

that have each been twisted an extra twist per inch than ordinary yarns

and combined to create a single thread. The yarn is spun so that it is

compact and solid. This cotton is used mainly for underwear, stockings,

and gloves. Colors applied to this yarn are noted for being more

brilliant than colors applied to softer yarn. This type of thread was

first made in the city of Lisle, France (now

Lille), hence its name.

[49][50][51]

International trade

Worldwide cotton production

The largest producers of cotton, currently (2009), are China and

India, with annual production of about 34 million bales and 33.4 million

bales, respectively; most of this production is consumed by their

respective textile industries. The largest exporters of raw cotton are

the United States, with sales of $4.9 billion, and Africa, with sales of

$2.1 billion. The total international trade is estimated to be $12

billion. Africa's share of the cotton trade has doubled since 1980.

Neither area has a significant domestic textile industry, textile

manufacturing having moved to developing nations in Eastern and South

Asia such as India and China. In Africa, cotton is grown by numerous

small holders. Dunavant Enterprises, based in

Memphis, Tennessee, is the leading cotton broker in Africa, with hundreds of purchasing agents. It operates

cotton gins

in Uganda, Mozambique, and Zambia. In Zambia, it often offers loans for

seed and expenses to the 180,000 small farmers who grow cotton for it,

as well as advice on farming methods.

Cargill also purchases cotton in Africa for export.

The 25,000 cotton growers in the United States are heavily

subsidized at the rate of $2 billion per year although China now provides the highest overall level of cotton sector support.

[52]

The future of these subsidies is uncertain and has led to anticipatory

expansion of cotton brokers' operations in Africa. Dunavant expanded in

Africa by buying out local operations. This is only possible in former

British colonies and Mozambique; former French colonies continue to

maintain tight monopolies, inherited from their former colonialist

masters, on cotton purchases at low fixed prices.

[53]

Leading producer countries

| Top 10 Cotton Producing Countries (in metric tonnes) |

| Rank |

Country |

2010 |

2012 |

2014 |

| 1 |

China China |

5,970,000 |

6,281,000 |

6,532,000 |

| 2 |

India India |

5,683,000 |

6,071,000 |

6,423,000 |

| 3 |

United States United States |

3,941,700 |

3,412,550 |

3,553,000 |

| 4 |

Pakistan Pakistan |

1,869,000 |

2,312,000 |

2,308,000 |

| 5 |

Brazil Brazil |

973,449 |

1,673,337 |

1,524,103 |

| 6 |

Uzbekistan Uzbekistan |

1,136,120 |

983,400 |

849,000 |

| 7 |

Turkey Turkey |

816,705 |

754,600 |

697,000 |

| 8 |

Australia Australia |

386,800 |

473,497 |

501,000 |

| 9 |

Turkmenistan Turkmenistan |

230,000 |

295,000 |

210,000 |

| 10 |

Mexico Mexico |

225,000 |

195,000 |

198,000 |

| Source: UN Food & Agriculture Organization[54] |

In

India, the states of

Maharashtra (26.63%),

Gujarat (17.96%) and

Andhra Pradesh (13.75%) and also Madhya Pradesh are the leading cotton producing states,

[56] these states have a predominantly tropical wet and dry climate.

Fair trade

Cotton is an enormously important commodity throughout the world.

However, many farmers in developing countries receive a low price for

their produce, or find it difficult to compete with developed countries.

On 27 September 2002, Brazil requested consultations with the US

regarding prohibited and actionable subsidies provided to US producers,

users and/or exporters of upland cotton, as well as legislation,

regulations, statutory instruments and amendments thereto providing such

subsidies (including export credits), grants, and any other assistance

to the US producers, users and exporters of upland cotton.

[59]

On 8 September 2004, the Panel Report recommended that the United

States "withdraw" export credit guarantees and payments to domestic

users and exporters, and "take appropriate steps to remove the adverse

effects or withdraw" the mandatory price-contingent subsidy measures.

[60]

While Brazil was fighting the US through the WTO's Dispute Settlement

Mechanism against a heavily subsidized cotton industry, a group of four

least-developed African countries – Benin, Burkina Faso, Chad, and

Mali – also known as "Cotton-4" have been the leading protagonist for

the reduction of US cotton subsidies through negotiations. The four

introduced a "Sectoral Initiative in Favour of Cotton", presented by

Burkina Faso's President Blaise Compaoré during the Trade Negotiations

Committee on 10 June 2003.

[61]

In addition to concerns over subsidies, the cotton industries of some

countries are criticized for employing child labor and damaging

workers' health by exposure to pesticides used in production. The

Environmental Justice Foundation has campaigned against the prevalent use of forced child and adult labor in cotton production in

Uzbekistan, the world's third largest cotton exporter.

[62] The international production and trade situation has led to "

fair trade"

cotton clothing and footwear, joining a rapidly growing market for

organic clothing, fair fashion or "ethical fashion". The fair trade

system was initiated in 2005 with producers from

Cameroon,

Mali and

Senegal.

[63]

Trade

Cotton is bought and sold by investors and price speculators as a

tradable commodity on 2 different stock exchanges in the United States

of America.

- Cotton No. 2 futures contracts are traded on the New York Board of Trade (NYBOT) under the ticker symbol CT. They are delivered every year in March, May, July, October, and December.[64]

- Cotton futures contracts are traded on the New York Mercantile Exchange (NYMEX) under the ticker symbol TT. They are delivered every year in March, May, July, October, and December.[65]

Critical temperatures

- Favorable travel temperature range: below 25 °C (77 °F)

- Optimum travel temperature: 21 °C (70 °F)

- Glow temperature: 205 °C (401 °F)

- Fire point: 210 °C (410 °F)

- Autoignition temperature: 360 °C (680 °F) - 425 °C (797 °F)[66]

- Autoignition temperature (for oily cotton): 120 °C (248 °F)

A temperature range of 25 to 35 °C (77 to 95 °F) is the optimal range

for mold development. At temperatures below 0 °C (32 °F), rotting of

wet cotton stops. Damaged cotton is sometimes stored at these

temperatures to prevent further deterioration.

[67]

British standard yarn measures

- 1 thread = 55 in or 140 cm

- 1 skein or rap = 80 threads (120 yd or 110 m)

- 1 hank = 7 skeins (840 yd or 770 m)

- 1 spindle = 18 hanks (15,120 yd or 13.83 km)

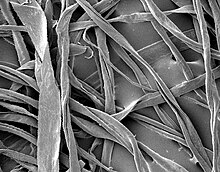

Fiber properties

| Property |

Evaluation |

| Shape |

Fairly uniform in width, 12–20 micrometers;

length varies from 1 cm to 6 cm (½ to 2½ inches);

typical length is 2.2 cm to 3.3 cm (⅞ to 1¼ inches). |

| Luster |

high |

Tenacity (strength)

Dry

Wet |

3.0–5.0 g/d

3.3–6.0 g/d |

| Resiliency |

low |

| Density |

1.54–1.56 g/cm³ |

Moisture absorption

raw: conditioned

saturation

mercerized: conditioned

saturation |

8.5%

15–25%

8.5–10.3%

15–27%+ |

| Dimensional stability |

good |

Resistance to

acids

alkali

organic solvents

sunlight

microorganisms

insects |

damage, weaken fibers

resistant; no harmful effects

high resistance to most

Prolonged exposure weakens fibers.

Mildew and rot-producing bacteria damage fibers.

Silverfish damage fibers. |

Thermal reactions

to heat

to flame |

Decomposes after prolonged exposure to temperatures of 150 °C or over.

Burns readily. |

The chemical composition of cotton is as follows:

Cotton genome

A public genome sequencing effort of cotton was initiated

[68]

in 2007 by a consortium of public researchers. They agreed on a

strategy to sequence the genome of cultivated, tetraploid cotton.

"Tetraploid" means that cultivated cotton actually has two separate

genomes within its nucleus, referred to as the A and D genomes. The

sequencing consortium first agreed to sequence the D-genome relative of

cultivated cotton (

G. raimondii, a wild Central American cotton

species) because of its small size and limited number of repetitive

elements. It is nearly one-third the number of bases of tetraploid

cotton (AD), and each chromosome is only present once.

[clarification needed] The A genome of

G. arboreum would be sequenced next. Its genome is roughly twice the size of

G. raimondii's. Part of the difference in size between the two genomes is the amplification of

retrotransposons

(GORGE). Once both diploid genomes are assembled, then research could

begin sequencing the actual genomes of cultivated cotton varieties. This

strategy is out of necessity; if one were to sequence the tetraploid

genome without model diploid genomes, the euchromatic DNA sequences of

the AD genomes would co-assemble and the repetitive elements of AD

genomes would assembly independently into A and D sequences

respectively. Then there would be no way to untangle the mess of AD

sequences without comparing them to their diploid counterparts.

The public sector effort continues with the goal to create a

high-quality, draft genome sequence from reads generated by all sources.

The public-sector effort has generated Sanger reads of BACs, fosmids,

and plasmids as well as 454 reads. These later types of reads will be

instrumental in assembling an initial draft of the D genome. In 2010,

two companies (

Monsanto and

Illumina), completed enough Illumina sequencing to cover the D genome of

G. raimondii about 50x.

[69]

They announced that they would donate their raw reads to the public.

This public relations effort gave them some recognition for sequencing

the cotton genome. Once the D genome is assembled from all of this raw

material, it will undoubtedly assist in the assembly of the AD genomes

of cultivated varieties of cotton, but a lot of hard work remains.